A key advantage for our company is professional experience in the field of heavy materials and thick thread. We are clear that our success depends on the success of our clients. We know that each company has its specific needs,so we work with personalized solutions, seeking to identify and meet the demand of each client. It is in this way that HighTex has earned the trust of important companies.

Production of big-bags (also known as FIBC bags or jumbo bags) is a complex process. The container itself might look simple: it is built just of four walls, sometimes supplemented with infeed and outfeed spouts allowing to fill the bag or discharge it.

In real life however we see clearly that even though the bag might look simple, the expectations of end-users grow every day, since they want to fill the containers with more and more expensive products, thus the FIBCs have to be built in a more and more advance way.

We also note that a significant number of customers are searching for machines not only to make the production process more automatic, but also to lower the production costs (reducing number of employees).

Therefore our goal is to deliver to our customers, big-bag manufacturers, machines typically connected with big-bag production, such as sewing heads, but also more completed solutions, allowing them to manufacture such components of big-bags as polypropylene tape, which might be used for production of fabric, as well as PE foil, used for manufacturing of liners.

HighTex came to the conclusion that it must give a possibility to its customers to have a constant grow of production potential.

It is our main goal to fulfill the expectations of our customers and we strongly believe that we will be able to deliver them solutions allowing them to enhance their production potential, including:

1. sewing lifting loop (or belt) to the body of the big bag

2. sewing the hemming of the body of the big bag

3. sewing the spout to the round shape open of the top cover

4. sewing the spout to the round shape open of the bottom cover

5. sewing the top cover to the body

6. sewing the bottom cover to the body

HighTex FIBC700 Big Bag Making Sewing Machine /Jumbo Bag Sewing Machine

One or Two Needle, Four thread, Chain Stitch sewing machine. It is used at side body sewing, lower leg, upper leg and cover sewing. The Double locked stitch container bag making machine standard supplied with built-in thread chain cutter.

Click here for video

HighTex FIBC300 Bulk bag sewing machine for stitching Jumbo Bags/Big Bag

Overlock + Chain (Safety) Stitch Sewing Machine with one-two needles. It is used at side body sewing, lower leg, upper leg and cover sewing. Equipped with thread chain cutter.

Click here for video

HighTex 72600 Jumbo Bag Sewing Machine with affordable price

It is basic heavy duty high speed "free stitch" sewing machine designed for attaching loops (lifting belts, handles) to the body of FIBC Jumbo bags and Big bag. One of the hallmark features of the 72600 is that it features a "free sewing" capability that allows the operator to sew in any direction free of the control of the walking foot, so you can sew zigzags,circles, squares, scalloped patterns any other arbitrary "pattern" with ease, when sewing straps (handles) of Big Bag /container bags.

Click here for video 1

Click here for video 2

HighTex 7367 High speed FIBC Jumbo bag sewing machine

It is one of the best Jumbo bag sewing machines in today market. It has been developed taking into consideration the requirements of FIBC jumbo bag, bulk bag, super sack or big bag. The "free sewing" capability that allows the operator to sew in any direction, allows effective jobs for belt attaching on a container bag, enforcement belt sewing, sling belt , large size parts sewing and so on.

Click here for video

FIBC911-400H High speed automatic Big Bags lifting loops sewing machine -- Sew lift loops to body of Polypropylene Bulk Bags better than any other machine built today!

From now on sewing of Bulk Bag lift loops will be quicker and easier, Ė donít waste your time, program your sewing on one lifting loops and you will see savings in no time.

Computerized sewing machine FIBC911-400H has achieved increased productivity with its maximum sewing speed of 1600 sti/min and beautifully finished seams with its new feed control system.

Click here for video

FIBC911-2040 Large area programmable pattern sewing machine perfect for stitching loop (lifting belts) to the body of Jumbo Bag, Container bags, Big Bag and bulk bag

Sew lift loops to body of Polypropylene Bulk Bags better than any other machine built today! This specialized Jumbo bag sewing automation is free programmable, so you can create any sewing pattern (for example X-Box, double W etc.) to meet customer's requirements. The wide sewing area 200 mm(X- axis) x 400 mm (Y- axis) allow the machine bed insert into body of Big Bag, Jumbo bags, Bulk bags, Super Sacks bag. Equipped with largest horizontal axis hook and extra large capacity bobbin (6 times bigger than normal bobbin)

Click here for video

MLK500-3520 Automatic programmable pattern sewing machine for attaching lifting loops/belts to soft tray FIBC, sling bags

Large rotary hook with 3 times bobbin capacity helps reduce the frequency of bobbin thread changing when sewing with thick thread (yarn). The extended sewing area is very helpful for attaching lifting loops /lifting belts to FIBC sling bag and soft tray container bag.

Click here for video

HighTex 53800 Long arm Jumbo bag sewing machine for Baffle sewing of container bags

Specially designed for Bafflle Sewing Of Container Bags. Specially suitable to sew straight lines into wide PP fabric without folding the fabric on the right side (Filler Cord from top & below can be stitched for sealing needle punctures).

Click here for video

HighTex 7243-37 Long arm industrial sewing machine for making FIBC sling bag

The 960mm (length) x190mm( High) extremely large clearance room under the arm is very helpful when you stitching webbing lifting loops /webbing belts at the middle of FIBC sling bag/soft tray sling bags.

One operator can finish the sewing work, great for saving labor cost!!

Click here for video

HighTex 828F High efficiency and high quality automatic Big Bag loop cutting machine at affordable price

HighTex automatic Jumbo Bag belt cutting machine is the specialist for accurate and efficient cutting of the webbing used for lifting loops /polypropylene straps/lifting belts in the production of FIBC Jumbo bag, Big Bag, soft tray container bag and FIBC sling bag. With this webbing(belt) cutting machine, the cutting and marking is done automatically through a PLC controlled system. An automatic counting feature eliminates waste by cutting the exact quantity required.

Click here for video

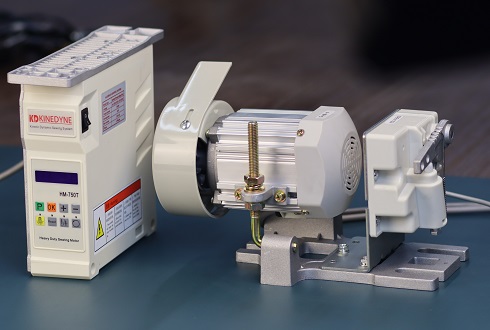

Kinedyne HM-750T the most powerful energy saving servo motor for heavy duty industrial sewing machines

A super powerful, quiet and reliable energy saving servo motor perfect for extra heavy duty webbing sewing machine. This high performance servo motor can save 60-80% electricity and improve 20-40% efficiency of the harness sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

Click here for 3D video

Click here for DEMO video

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!

|