|

|

|

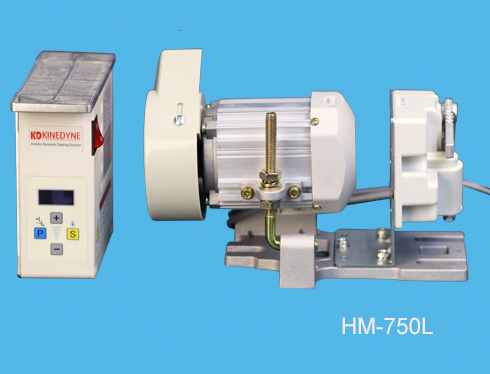

HM-750L Super Powerful, Quiet and Reliable Energy Saving Servo Motor for Extra Heavy Duty Industrial Sewing Machines (without Pneumatic System) for sale in United States

This high torque servo motor is specifically designed for basic leather sewing machines and other extra heavy duty industrial sewing machines that do not have pneumatic foot lift & reverse stitch and automatic thread trimmer.

Achieve fully adjustable speed control with this low cost but reliable servo motor. Speed is adjustable by a simple setting (from 300RPM to 3000RPM) that allowing you to slow down your machine and sew STITCH BY STITCH.

The premium quality needle positioning servo motor with synchronizer generates a tremendous amount of power (750W/1HP) and torque (7.9 Nm) at low speed, this makes sewing detailed work much easier. Also ideal for leather working beginner.

This energy saving servo motor allows for a more stable amperage draw, and reduces the energy consumption by an astonishing 60%-80% and improve 20-40% efficiency of the sewing machines. Instantly reduce your energy and operation costs when you install this sewing machine motor. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

The silent electric servo motor is much more powerful than othre power saving motor in today market, such as Juki #JIN-PSM-E750W, Ho Hsing G60 and ISM SV-71 650w.

Read More

|

|

|

HM-750T Extra Powerful, Silent and Durable Brushless Servo Motor for Extra Heavy Duty Industrial Sewing Machines (with Pneumatic System)for sale in United States

Kinedyne HM-750T is a most powerful, quiet and reliable energy saving servo motor perfect for all types of advanced heavy duty industrial sewing machines that equipped with pneumatic foot lift & reverse stitch, automatic thread trimmer and needle cooler etc. A great upgrade of your conventional clutch motor.

This powerful and efficient servo motor can save 60-80% electricity and improve 20-40% efficiency of the sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

The variable speed servo motor features in fully speed adjustable, quick start and precise positioning brake, this makes sewing detailed work much easier. Also ideal for beginners. This high torque servo motor generates a tremendous amount of power and torque at low speed.

The silent electric servo motor creates a more comfortable and concentrated sewing environment for your workshop.

With Kinedyne needle positioner synchronizer, you can program your heavy duty sewing machine to stop needle in the down position AND (not OR) in the up position which is not found on competitors' servo motors.

Read More

|

|

|

HM-750SL Low Speed, High Torque, Electronic Servo Motor for Medium and Heavy Duty Industrial Upholstery Sewing Machines (Perfect Speed Control) for sale in United States

Kinedyne HM-750SL is the world's most powerful class of "low-speed, high-torque" energy saving servo motor that maintains full power and torque even at low speeds. Its robust power and precise motions combine to deliver unparalleled performance. The minimum motor is down to 50 RPM, therefor the minimum of sewing machine speed can be down to 10 stitch per miniute, almost stitch by stitch. This makes sewing detailed work much easier. Also ideal for beginners.

Using either an 750SL high torque motor on heavy thick sewing applications completely eliminates the need for a now obsolete, "Speed Reducer". This powerful and efficient servo motor can save 60-80% electricity and improve 20-40% efficiency of the sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster. This sewing motor adopts Photoelectric sensor (instead of Hall sensor) that assures stable & accurate speed control. These motors run gently and smoothly when motor shifts between low, middle and high speed. In terms of performance and reliability, the Kinedyne HM-750SL is one of the best heavy duty leather sewing machine servo motor in today market!

Read More

|

|

|

HM-750SH Low Speed, Ultra High Torque, Electronic Servo Motor for Extra Heavy Duty Industrial Leather Sewing Machines - Perfect Speed Control

-- One of the Best Sewing Machine Servo Motor for American Leather Crafters & Saddlers

Kinedyne HM-750SH is the world's most powerful class of "low-speed, high-torque" energy saving servo motor that maintains full power and torque even at low speeds. Its robust power and precise motions combine to deliver unparalleled performance. The minimum motor is down to 50 RPM, therefor the minimum of sewing machine speed can be down to 10 stitch per miniute, almost stitch by stitch. This makes sewing detailed work much easier. Also ideal for beginners.

Using either an 750SH high torque motor on heavy thick sewing applications completely eliminates the need for a now obsolete, "Speed Reducer". This powerful and efficient servo motor can save 60-80% electricity and improve 20-40% efficiency of the sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster. This sewing motor adopts Photoelectric sensor (instead of Hall sensor) that assures stable & accurate speed control. These motors run gently and smoothly when motor shifts between low, middle and high speed. In terms of performance and reliability, the Kinedyne HM-750SH is one of the best heavy duty leather sewing machine servo motor in today market!

Read More

|

|

|

HM-1000SH Low Speed, Ultra High Torque, Powerful Servo Motor for Extra Heavy Duty Industrial Long Arm Sewing Machines (Perfect Speed Control) for sale in United States

The new generation HM-1000SH motor is available from Kinedyne. This extra powerful heavy-duty electric servo motor delivers crushing torque for industrial sewing machines. The 1000 Watt / 1.3 horsepower motor can drive the most heavy-duty industrial sewing machines and consistently delivers reliable control. This compact servo motor is also capable of handling many functions such as pneumatic foot lift/ reverse stitch, tape cutter, Jog Dial and much more.

Kinedyne is dedicated to producing the best quality heavy duty electric servo motors and ensuring customer satisfaction. Kinedyne implements American quality control systems that deliver long lasting quality for all of our motors. Kinedyne servo motors are known for their reliability, precision, and performance. They are designed to provide smooth and accurate control over speed, torque, and position. Kinedyne servo motors are built with durable components and undergo rigorous quality control measures to ensure their longevity and reliability. Whether you're a professional tailor, leatherworker, or other heavy-duty sewer, the Kinedyne brushless servo motor is a reliable choice that will enhance your sewing experience.

It is an excellent replacement of Ho Hsing i90 servo motor, Ho Hsing HVP-90 digital servo motor, and Efka expensive sewing servo motors.

Try the new Kinedyne HM1000SH and take your manufacturing or hobby to the next level today!!

Read More

|

|

|