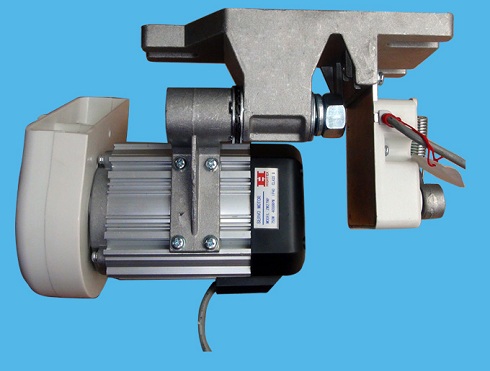

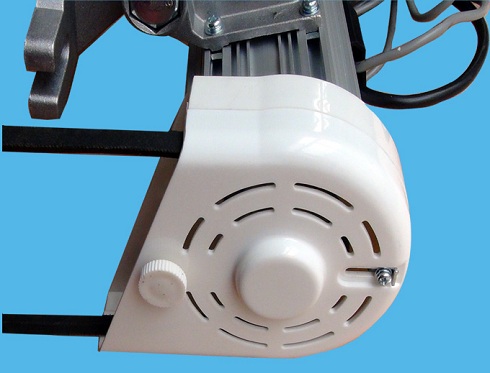

The strong Servo motor for heavy duty industrial sewing machines: Powerful + Quiet + Accurate Speed Control

As result of 20 years of working experience with heavy duty industrial sewing machine, we know well how to make a proper servo motor.

HIGHTEX HVP series heavy sewing machine Servo Motors use the latest sewing technology to provide unparalleled power and torque.

Main Features:

1. Powerful—Real 750W output, it can drive 733 class e heaviest industrial sewing machine well.

(Click here for video )

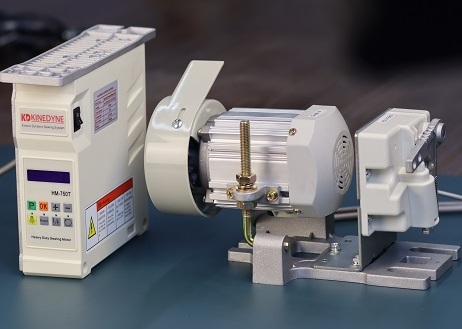

Kinedyne HM-750T New powerful servo motor for heavy duty industrial sewing machines (slow speed high torque energy saving servo motor with affordable price).

2. Quiet-- the noise that is normally associated with sewing motors (clutch motor) is almost entirely eliminated, creating a more pleasant work environment.

3. Accurate Speed Control—speed is adjustable by simple setting (from 100 to 4800RPM). This makes sewing detailed work much easier.

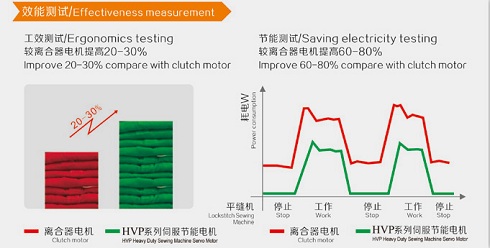

4. High efficiency, can improve labor efficiency 20%~30%.

5. Energy saving feature saving up to 60%-80% in energy costs.

6. Uses 150 degrees Celsius high performance rare earth permanent magnetic materials to ensure product stability and reliability.

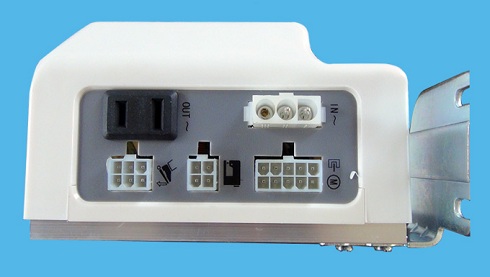

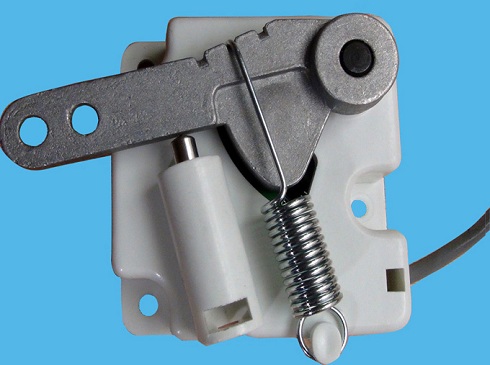

7. Additional control box is available as optional for supporting pneumatic presser foot lift, pneumatic reverse stitch, pneumatic center seam guide, switchable thread tension and needle cooler etc.

8. Work together with Speed Reducer to reach “Step Stitch” function (Precision step-by step stitching for detailed sewing, allows for one stitch at a time sewing by leather workers or anyone who needs stitch by stitch control for small items and turning corners.)

This is a breakthrough in servomotor technology, the 9-coil design, the torque is so strong you can't hold the pulley with your hand (more torque even then a clutch motor).

It is the REAL servo motor for heavy duty industrial sewing machines, different from other motors so call “Energy Saving Servo Motor”, “Power Saving Servo Motor” or “Brushless Dc Servomotor” in the market (see the detailed difference at: )

Through the electronic engine, the machine is easy to operate, even for inexperienced operators. For example, is possible for very smooth start of the machine or even a stitch-by-stitch sewing with this machine.

Specifications:

Model number: HVP-70 / HVP-50

Input voltage: 220V/110V

Frequency: 50/60HZ

Output: 750W (HVP-70) / 550W (HVP-50)

Max. Torque: 5.0 N.M / 6.5N/M

Speed Range: 100-4800 RPM

Needle positing precision: 5 degree (for HVP-50 with additional synchronizer)

Net weight: 6.8 KGS / 5.9KGS

Packing size: 390×300×210mm

|