A key advantage for our company is professional experience in the field of heavy materials and thick thread. We are clear that our success depends on the success of our clients. We know that each company has its specific needs,so we work with personalized solutions, seeking to identify and meet the demand of each client. It is in this way that HighTex has earned the trust of important companies. HighTex also manufacture machinery for sewing other thick materials, with customized machines according to the needs of each client. And in our desire to improve and innovate, we do not stop developing techniques for heavy duty sewing, with constant activity in technology for sewing thick materials that makes us have a deep knowledge in heavy industries activity with an exhaustive and permanent training updated of the technological evolution for the manufacture of thick fabrics.

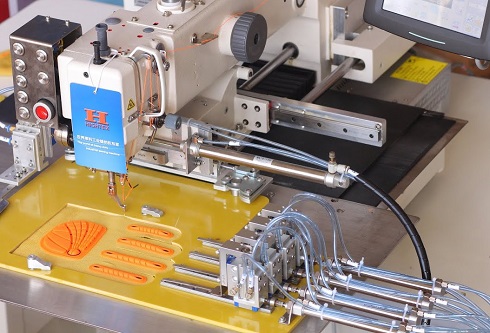

MLK200-3020SG Automatic safety gloves sewing machine for stitching the rubber TPR on back palm of gloves, recommend for safety work glove and industrial gloves manufacturers in india

It is custom made automatic sewing machine for stitching the rubber TPR on back palm of gloves. One worker can operate 2 automatic safety glove sewing machine at same time, great for labor saving!!! No need to hold the protecting rubber TPR by hand during the sewing operation, working at Absolute Safety!!

Click here for video on YouTube

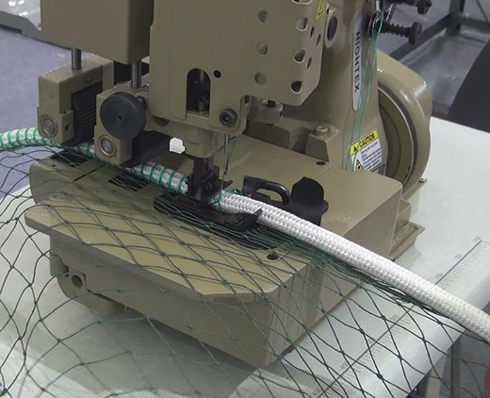

FIBC500 1 needle 3 threads overedging sewing machine for attaching ropes to net wtih twin puller, recommend for Saftey Net, Sport Net and Fishing Net Manufacturers in India

This single needle three thread overedging sewing machine is perfect for attaching thick ropes to net borders. It is designed to satisfy the increasing demand for machines that sew thicker nets (rope inserts up to 20 mm in diameter).

Click here for DEMO video

430FX Heavy duty bar tacking sewing machine for joining ropes in the manufacturing safety nets and sports nets

High speed automatic safety nets sewing machine to stitch lateral half mesh of knotless nets, ideal for the manufacturing of safety nets and special nets for a variety of applications including cargo handling, debris, hoisting, climbing, and fall protection.

Click here for DEMO video

MLK500-2516N Automatic webbing cargo nets sewing machine

The biggest advantage of this custom made cargo netting sewing machine is the large space behind needle, that allow you to fold large size of webbing cargo nets during the sewing.

Click here for DEMO video

MLK500-2516ECO Heavy duty programmable pattern sewing machine for bar-tacking seams on screamers (shock absorbing sling)

This automatic shock absorbing sling (screamers) sewing machine features in 3 times large bobbin capacity that allow you to use very thick sewing thread.

Click here for DEMO video

9204ZZ Heavy duty walking foot Zig Zag sewing machine for carpets, rugs and floor mats, recommend for Car Floor Mats Manufacturer in India

The Zig-Zag Width (up to 16 mm) is bigger than any other industrial zigzag sewing machine built today,ideal for assembling (jointing) 2 pieces of carpets together by stitching. Powerful walking foot mechanism insures the smooth feeding of hard-to-feed materials or multi-layered sections of materials to achieve consistent seam quality that is free from irregular stitch pitches.

Click here for video

205-370BH Heavy duty triple feed sewing machine with synchronized binder for rug and carpet binding, recommend for shoes & footwear manufacturers in India

It is vibrating binder attachment and due to this feature, a beautiful tape binding finish for heavy materials or elastic tape can smoothly and easily be performed. The Adler 205 type large Barrel shuttle hook on this industrial sewing machine is designed for sewing heavy weight materials & thick sewing threads.

Click here for video

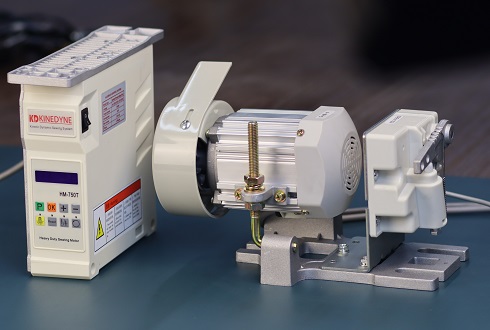

Kinedyne HM-750T the most powerful energy saving servo motor for heavy duty industrial sewing machines

A super powerful, quiet and reliable energy saving servo motor perfect for extra heavy duty webbing sewing machine. This high performance servo motor can save 60-80% electricity and improve 20-40% efficiency of the harness sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

Click here for 3D video

If you have any questions or concerns, please feel free to contact us at asia@automatic-sewing.com, thank you! |