|

|

|

72600 Inexpensive heavy duty FIBC Jumbo bag sewing machine for sale in Uzbekistan

This machine is designed for universal use in the manufacturing of heavy duty Flexible Intermediate Bulk Container (FIBC), Big Bag, bulk bags, sling bags, baffle bag, bulk liner, net bags, jute bags and Jumbo Bags made of thick woven polyethylene, polypropylene, geotextile, PE tarpaulin, three-dimensional (3D) spacer fabric and other very heavy & hard bag fabrics. Equipped with revolutionary new powerful servo motor for heavy duty industrial sewing machine (very powerful, silent & reliable energy saving servo motor with affordable price).

1. Making side seams on heavy weight fabrics with thick thread, and all other LOCKSTITCH seams on body of container bags;

2. Assembling layers of PP webbings together for making lifting loops (container belts) of Big Bag, with various reinforced seams, such as X-Box;

3. Sewing and attaching side seam loops or cross corner loops (container belts) by reinforced stitching;

4. Inserting top covers and attaching filler cord and discharging tubes with cords from the too and/or from below for sealing the left needle punctures;

5. 3-D spacer fabric construction: stitch layers of spacer fabrics together with thickness up to18mm;

6. Use as FIBC bag repair machine for patch and mend jute sacks, Polypropylene (PP) Big Bags, Container Bags, tents and awnings (replace Newlong DD-5, Seiko SK-8, Singer 133K-18)  Click here for watching video Click here for watching video |

|

|

7367 High speed heavy duty industrial sewing machine for Jumbo Bags - Big Bag making industry in Uzbekistan

It is the latest sewing technology for the Jumbo Bags - Big Bag making industry, the new technologies of this machine are optimal conditions for manufacturing of container bags and Big Bags:

1. High sewing speed up to 1600 RPM;

2. Up to 14mm big stitch length;

3. With its strong top and bottom feed mechanism, the machine insures the smooth feeding of hard-to-feed materials or multilayered sections of materials to achieve consistent seam quality that is free from irregular stitch pitches;

4. The presser foot has an extra high lift and can go up to 18mm, allowing for a large range of extra heavy weight material to be used;

5. The automatic lubricating mechanism dramatically improves maintainability of the machine;

6. Equipped with largest horizontal axis hook and extra large capacity bobbin (6 times);

7. Its features a "free sewing" capability that allows the operator to sew in any direction, allows effective jobs for belt attaching on a container bag, enforcement belt sewing, sling belt , large size parts sewing and so on. Equipped with revolutionary new powerful servo motor for heavy duty industrial sewing machine (very powerful, silent & reliable energy saving servo motor with affordable price).

Click here for watching video Click here for watching video |

|

|

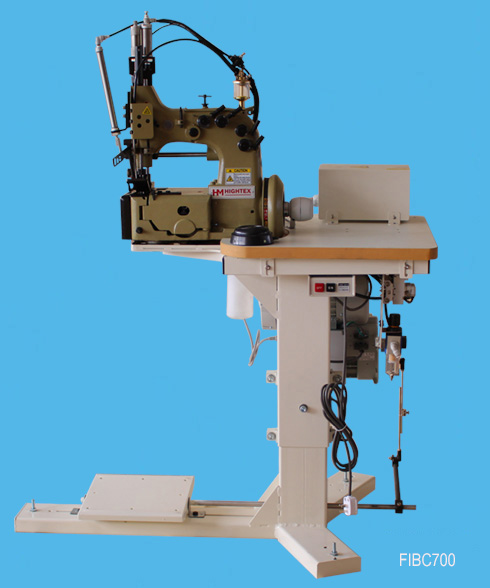

FIBC700 Heavy duty two needle double locked stitch sewing machine with top and bottom feed for making single loop bag, double loop bag, Container bag and Baffle-Bag (Q-Bag)

Two needle independent row, double locked stitch machine for even matched seaming of Big Bag/container bags and simultaneously attaching belt band. Its design and pedestal installation makes it especially suitable for attaching filling and discharging tubes and inserting top covers. Guides for filler cord from the top and / or from below for sealing the needle punctures of the left needle.

This Big Bag/Container bag making machine is interchangeable with Newlong DR-7UW series SINGLE NEEDLE AND TWO NEEDLE INDEPENDENT ROWS DOUBLE LOCKED STITCH MACHINES with Lower and Upper Feed.  Click here for watching video Click here for watching video |

|

|

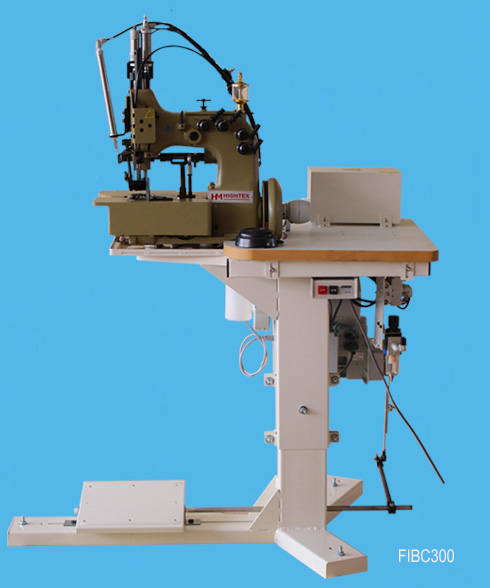

FIBC300 Safety stitch machine with lower feed and alternating upper feed for Jumbo bags, bulk bags, container bag

Two needle machine four thread safety stitch machine. Lower and upper feed. Adjusted for polypropylene sewing threads for matched seaming of very heavy bag fabrics make of jute, burlap or woven polypropylene with a 10 mm wide overedge stitch on the fabric edge and in a distance of 5mm (13 gauge) to this with an additional double locked stitch.

This FIBC Big bag sewing machine is supplied with guides for filler cord from the top and / or from below for sealing the needle punctures of the left needle. High needle stroke sewing machine for very strong side seams in the production of very heavy weight jute, burlap or woven polypropylene bags (container bags).

This Big Bag/Container bag making machine is interchangeable with Newlong HR-6 series TWO NEEDLE FOUR THREAD SAFETY STITCH MACHINES with Lower and Upper Feed.

Click here for watching video Click here for watching video |

|

|

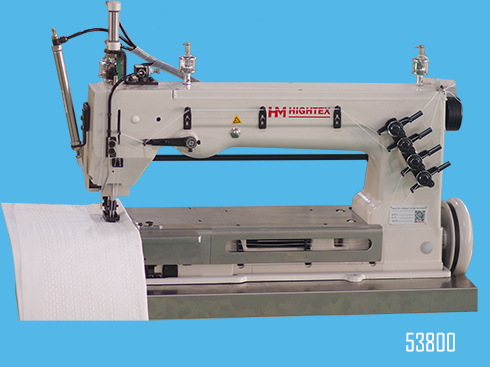

53800 Long arm Jumbo bag sewing machine for Baffle sewing of container bags in Uzbekistan

Double Needle, Four Thread, Long Arm Chain Stitch Sewing Machine With Lower Feed & Alternating Upper Feed, specially designed for Bafflle Sewing Of Container Bags. Specially suitable to sew straight lines into wide PP fabric without folding the fabric on the right side (Filler Cord from top & below can be stitched for sealing needle punctures)

This double needle, four thread Baffle bag sewing machine standard with single needle attachment for one needle/two thread sewing operatioin.

Sewing automation, such as pneumatic presser foot lift, neumatically operated hot thread chain cutter, automatic needle position servo motor and automatic lubrication.

Click here for watching video Click here for watching video |

|

|

FIBC911-2040 Large area programmable pattern sewing machine perfect for stitching loop (lifting belts) to the body of Jumbo Bag, Container bags, Big Bag and bulk bag

Rcommend for FIBC Bulk Bags Manufactured in Uzbekistan

Upto 1200 rpm high sewing speed guarantees high efficiency; The wide sewing area 200 mm(X- axis) x 400 mm (Y- axis) allow the machine arm insert into body of Big Bag, Jumbo bags, Bulk bags, Super Sacks bag;The extra large rotary hook and bobbin capacity (6 times bigger than normal hook) reduces the number of bobbin changes even for thick thread; A one-person operation that is reliable and easy to use by automatically pulling Big Bag body (before sewing); This specialized automatic Jumbo bag belt sewing machine is free programmable, so you can create any sewing pattern (for example X-Box, double W etc.) to meet customer's requirements;

Ver easy to use and maintain, no need of skilled worker, great for reducing labor costs;

This programmable Big Bag loop sewing machines are completely assembled and delivered by strong plywood case (Ready To Sew out of box).

Click here for watching video Click here for watching video

|

|

|