|

|

|

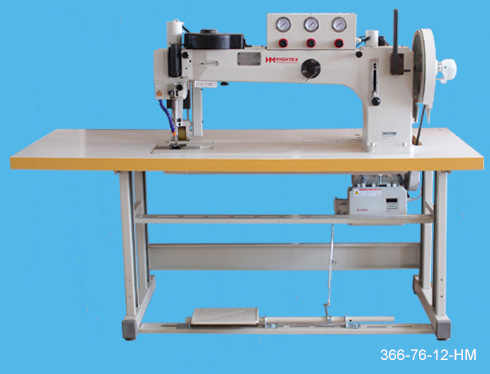

366-76-12-HM Extra heavy duty long arm tiple zigzag sewing machine with large Barrel shuttle and puller feed for sail makers and repairs in Mexico

This specialized sail making machine gives large working space underarm eliminates the effort and time needed to fold and roll wide sections of sailcloth and cover fabrics during sewing operations; This machine is recognized as the ultimate sail maker sewing machine currently available, it is capable of powering its needle through 20mm of Dacron, Kevlar, Webbing, Canvas and leather; Extremely strong needle penetration force, can easily sew sturdy webbing reinforcement and extra heavy sail corner patches; The large shuttle hook and bobbin capacity reduces the number of bobbin changes and offer high efficiency in sewing sails, tents and tarpaulins, using extra thick thread up to size V277; With 4 Cams for straight stitch, 1-step (2-points), 2-step (3-points), 3-step (4-points) zigzag, cover all demands of modern sail making industry; Standard supplied with heavy duty top and bottom feed puller, which is perfect for sail makers; This robust and reliable sail sewing machine is designed for mass-production sail making business (similar with Durkopp Adler 366-76-12-HM).  Click here for video Click here for video |

|

|

9518-30 Long arm zigzag sewing machine for spinnakers and windsurfing sails in Mexico

The application covers straight stitch, 1-step, 2-step, 3-step and 4-step zigzag in production of spinnakers sails, and up to medium heavy sails; It employs a parallel vertical needle bar motion for stronger striking power and can easily sew sturdy webbing reinforcement and heavy duty corner patches; This spinnakers machine is capable of powering its needle through 7 mm of Dacron, Kevlar, Webbing, Canvas and leather; The heavy duty built-in puller behind the pressure foot helps sail makers create a smooth, even stitch on windsurf sail; A wide range of sewing threads can be used: V46, V69, V92 & V138; Its modern design features: a zigzag width of up-to 10 mm and a stitch length of up-to 5 mm; It is interchangeable with Durkopp Adler 72525, therefore it is easier for the sail lofts already worked with Adler 525 spinnakers sewing machine.Equipped with powerful electric servo motor (energy saving motor) with speed control and needle positioning.

Click here for video Click here for video |

|

|

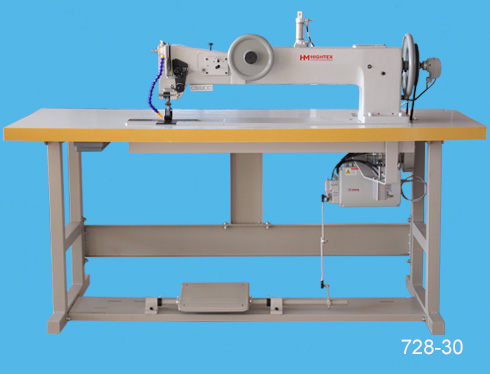

728-30 Extra heavy duty double needle triple feed long arm industrial sewing machine for manufacturers of tents, parachutes, upholstered furniture, covers, Silt Curtain and Geotextile tubes in Mexico

Long and wide working space is suitable for sizable materials such as military tents, tarpaulins, sails and canvas sheeting etc; It features a triple feeding action by way of: bottom feed, needle feed and walking foot top feed that can easily sew layers of slippery materials; Is fitted with two extra large vertically mounted hook & bases (6 times bigger compare to regular industrial sewing machine) for sewing with very thick thread up to Nm 10/3; Up to 10 mm long stitches for decorative topstitching seams; Excellent climbing properties and high needle penetration power guarantee easy sewing thick spots or cross seams, without skipped stitch, loosing bottom thread and shorten stitch length; A safety clutch is fitted to help prevent damage to the hooks, bevel gears and other important parts, should the machine become jammed or over-loaded; Heavy duty top and bottom feed puller is available as option. Standard supplied with powerful sewing machine servo motor with speed control and needle positioning.

Click here for video Click here for video |

|

|

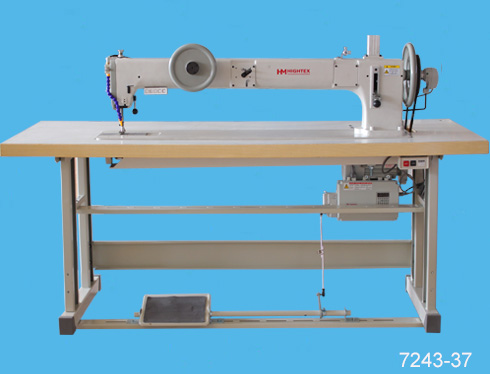

7243-37 Super long arm extra heavy duty barrel-shuttle type compound feed lockstitch sewing machine for sale in Mexico

The sewing machine arm has been extended (complete casting, not a cut and piece extended arm) to give approximately 960mm clearance, which is very useful when sewing larger items, for example: sails, tents, covers etc.; The walking foot action is fully driven and combines with the bottom feed and needle bar feed to produce a positive feeding motion for extra heavy use; It is fitted with an extra large shuttle hook assembly (204 type) for use with heavy weight & extra heavy weight materials and extra thick threads; The presser foot has an extra high lift and can go up to 23mm, allowing for a large range of heavy & extra heavy weight material to be used. Standard supplied with strongest sewing machine servo motor with speed control and needle positioning.

Click here for video Click here for video |

|

|

204-76-370 Heavy duty triple feed long arm upholstery sewing machine with large Barrel shuttle hook for thick thread decorative stitches on sofa & armchair, covers, marine & auto upholstery in Mexico

This heavy duty industrial sewing machine arm has been extended to give 760mm clearance, which is very useful when sewing larger panel, for example: lounge sofa, car seat, marine upholstery etc.; It is fitted with an extra large shuttle hook assembly (204 type) for use with heavy weight & extra heavy weight materials and extra thick threads; Constant stitch lengths due to optimized triple feed mechanism, even in case of extremely thick materials; Excellent stitch pattern and constantly tight stitches, even when sewing with extremely thick threads up to Nm 8/3 or 1.4mm braided thread; The sewing foot stroke up to 10 mm allows the safe climbing over differently high material plies; This long arm industrial sewing machine with a cheaper price than others on the market offers average European quality standards. Standard supplied with strongest sewing machine servo motor with speed control and needle positioning.<

Click here for video Click here for video |

|

|

733-30 Long arm extra heavy duty lockstitch machine for manufacturers of sails, tents, parachutes,furniture, silt curtains and Geotextile tubes in Mexico

This extra heavy duty top and bottom feed lockstitch machine comes with a 760 mm long arm clearance and extra wide bed to make it easy to sew large articles; The large machine pulley helps the machine to attain strong striking power - thus making sewing on multi-layer extra heavy material, whether slippery or gummy simple; The cam thread take up and large shuttle hook with large bobbin capacity mean less down time for bobbin changes, even using extra thick thread and has a thread rating up-to size T-700 (=2000d X3 or V693); Its extra high foot lift (32 mm) and long needle bar stroke make it the ideal machine in the sewing of extra heavy weight materials; Standard delivered with pneumatic presser foot lift, pneumatic reverse stitch and needle cooler. Standard supplied with strongest sewing machine servo motor with speed control and needle positioning.

Click here for video Click here for video |

|

|

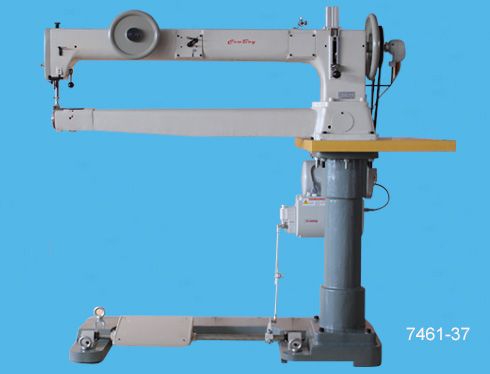

7461-37 Super long arm cylinder bed heavy duty compound feed lockstitch machine

7411RL-37 Long arm cylinder bed transverse seam machine (Feed up the arm)

The sewing machine cylinder shaped arm has been extended (complete casting, not a cut and piece extended arm) to give approximately 960mm clearance, which is very useful when sewing larger items, for example: golf bags, luggage bags, industrial boots, covers etc.; The special extra long feed up the arm cylinder machine is suited to sewing for example: large tubular shapes, golf bags, luggage bags, tents, sails, parachutes, umbrellas, fishing gear, cushions etc.; It is fitted with an extra large shuttle hook assembly (204 type) for use with heavy weight & extra heavy weight materials and extra thick threads; The presser foot has an extra high lift and can go up to 23mm, allowing for a large range of heavy & extra heavy weight material to be used. Standard supplied with strongest sewing machine servo motor with speed control and needle positioning.  Click here for video Click here for video |

|

|

7510NL-25 Long arm walking foot industrial sewing machine for sewing upholstery, tarpaulins, awnings and camping equipment in Mexico

Features: This heavy duty industrial sewing machine comes with a 635 mm long arm clearance to make it easy to sew large articles, such as upholstery, tarpaulins, awnings and camping equipment; The new mechanism with a rectangular feeding motion promises consistent feed of materials of all thickness without stitch gathering; The lower orbit of the feed dog prevents the material from flopping and reduces operating noise and vibration; Automatic lubricating mechanism helps improve maintainability, The machine is provided with a sub oil pan and double filter to keep dust from entering the oil; The machine is equipped with a bottom-feed adjusting mechanism that adjusts the amount of bottom-feed while keeping the needle feed fixed, with this adjusting mechanism, the machine can prevent uneven material feed without changing stitch pitches. Equipped with powerful electric servo motor (energy saving motor) with speed control and needle positioning.

Click here for video Click here for video

|

|

|

|