|

|

|

828 Low cost automatic hot knife webbing cutting machine for Australia manufacturer of ratchet strap and safety harness

The lowest cost heavy duty automatic hot knife cutting machine for cargo lashing belts and safety harness webbing available on the market today. The temperature of hot blade is upto 600 C, can cut all types synthetic webbing slings made of Nylon, Polyester and Polypropylene;Temperature, cutting length, production quantity, cutting time all programmable; Cut and seal the material in same time for simple future processing; Top and bottom feed mechanism ensures precise cutting length; With CE certificate (CE approved).

Click here for video Click here for video |

|

|

828A Automatic hot knife webbing cutting machine for ratchet strap manufacturer in Australia and safety harness manufacturer in Australia

Most hot knife webbing cutting machines in today market are designed for light weight webbing tapes for straps and belts used in fashion industry. Hightex 828A is a professional hot cutting machine for heavy duty synthetic straps, belts, harnesses and Webbing; Excellent price/performance ratio; Cut and seal the material in same time for simple future processing; Can cutting 2-3 narrow webbing once (depend on the width of webbing); Top and bottom feed mechanism ensures precise cutting length; With CE certificate (CE approved).

Click here for video Click here for video |

|

|

828B Automatic hot knife cutting machine with 2 heating blades, for heavy duty polyester webbing slings in Australia and climbing ropes manufacturer in Australia

This heavy duty automated webbing hot cutting machine is same to 828A, but equipped with 2 heating blades, greatly improve cutting efficiency, and prevent from burrs. Hightex 828B is a professional hot knife cutting machine for both heavy duty lifting slings and straps, as well as cargo lashing straps and safety harness webbing; Can cutting 2-3 narrow webbing once (depend on the width of webbing); Excellent price/performance ratio; Cut and seal the material in same time for simple future processing; Top and bottom feed mechanism ensures precise cutting length; With CE certificate (CE approved).

Click here for video Click here for video |

|

|

828BW-S400 Automatic hot knife cutting machine for 300mm wide webbing slings

This unique hot cutting machine is designed for automatic cutting, measuring and sealing 10,000kg webbing sling (300mm wide) in the production of 10,000 KGS (10T) extra heavy duty lifting slings and wide body cargo slings made of Nylon and Polyester.

Equipped with 2 hot blades with each of 600C (Max. temperature)

Application: 10,000 KGS (10T) extra heavy duty lifting slings and wide body cargo slings made of 300mm wide webbing strap, regular lifting slings, lifting straps, crane slings, rigging slings, industrial lifting belts, ratchet straps, lashing straps, safety belts, rescue belts, safety lanyard, military webbing straps

Click here for video Click here for video |

|

|

828C Heavy duty automatic hot knife webbing cutting machine with rotating knife for straight and angle cutting (-45°/+45°)

Most hot knife webbing cutting machines in today market are designed for light weight webbing tapes for straps and belts used in fashion industry. Hightex 828C is a professional hot cutting machine for heavy duty synthetic straps, belts, harnesses and Webbing; Excellent price/performance ratio; Cut and seal the material in same time for simple future processing; Top and bottom feed mechanism ensures precise cutting length; With CE certificate (CE approved).

Application: fall protection equipment & safety harness, seat belts, heavy duty lifting slings, lifting straps, crane slings, rigging slings, army webbing, military equipment and other industrial lifting belts, ratchet straps, lashing straps, safety belts, rescue belts, safety lanyard, military webbing straps.

Click here for video Click here for video |

|

|

828BM-E300 Automatic webbing cutting, measuring, marking and stacking machine for lifting sling manufacturer in Australia, ratchet strap manufacturer in Australia and safety harness manufacturer in Australia

828BM-E300 is highly efficient hot knife automatic webbing cutting machines, especially designed for the lifting slings, lashing strap and safety harness industries.

They feature an easy-to-adjust marking system that simultaneously adds up to six ink marks to the webbing straps that then becomes the reference for proper placement and sewing on lifting slings, cargo lashing strap and safety harness.

The length for cutting and the position of the reference marks for sewing in the subsequent making process can be programmed into the controller.

The machine automatically cuts the webbing strap and marks their position for subsequent sewing.

Application: fall protection equipment & safety harness, seat belts, heavy duty lifting slings, lifting straps, crane slings, rigging slings, army webbing, military equipment and other industrial lifting belts, ratchet straps, lashing straps, safety belts, rescue belts, safety lanyard, military webbing straps.

Click here for video Click here for video |

|

|

828-UV60-WG Automatic length cutting, measuring and winding machine for ratchet straps and tie down straps manufacturer in Australia

The HIGHTEX 828-UV60-WG is designed as a flexible and automatic cutting, measuring and winding system for a wide range of applications, such as cargo lashing straps and harness webbing. Its flexibility fits well to the requirements of various cutting and winding applications and also covers a wide range of winding dimensions up to roll or bobbin diameter of 300 mm. Based on many years of experience in the design of winding, cutting and confection machines, the 828-UV60-WG obtains a high process reliability and avoids typical textile problems, such as knots, roll and bobbin deformation, tension variations, loops or distortion; With CE certificate (CE approved).

Applications: ratchet straps, lashing straps & tie down strap, safety harness, rescue belts, safety lanyard, military webbing straps and seat belts.

Click here for video Click here for video |

|

|

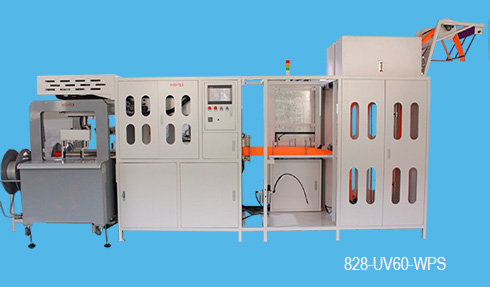

828-UV60-WPS Fully automatic webbing cutting, measuring, winding and packing machine, for ratchet straps and tie down straps manufacturer in Australia

This machine can make a revolution in your production of cargo lashing straps, that realize fully automation (from measuring, cutting, winding to packing finished product, without worker involve in) for the production of cargo lashing strap.

In a traditional manufacturing setup, 2 workers for measuring and cutting webbing strap, 1 worker for winding and 1 workers for packing, total 4 workers.

With 828-UV60-WPS automation equipment, all above tasks can be accomplished by 1 worker, further moreover, this workercanoperate multiple machines at same time (two 828-UV60-WPS machines or one 828-UV60-WPS + another automatic machine such as MLK600 automatic ratchet lashing strap sewing machine. Save labor cost up to 500%!

Process automation is essential in today's industry because competitiveness requires higher levels of reliability, productivity, quality and profitability.

We provide complete industrial automation solutions using state-of-the-art hardware and software tools to achieve the proposed goal.

Think hard before buying this automation equipment: "When machine no longer need workers, where are your workers going?"

Click here for video Click here for video |

|

|