|

A key advantage for our company is professional experience in the field of heavy materials and thick thread. We are clear that our success depends on the success of our clients. We know that each company has its specific needs,so we work with personalized solutions, seeking to identify and meet the demand of each client. It is in this way that HighTex has earned the trust of important companies.

We have in-house technicians who have over 20 years of combined experience in servicing and repairing these special sewing and cutting equipment used in manufacturing of lashing straps (Ratchet tie-down strap). HighTex heavy duty automatic sewing machines and automated cutting machines have been widely used by worldwide cargo lashing straps manufacturers in United States, Germany, Italy, United Kingdom, Argentina, Armenia, Australia, Belarus, Belgium, Brazil, Bulgaria, Canada, China, Colombia,Czech Republic, Fiji, Finland, India, Indonesia, Iran, Israel, Japan, Lithuania, Latvia, Malaysia, Mexico, Netherlands, New Zealand, Peru, Poland, South Korea, Romania, Russia, Serbia, Singapore, South Africa, Sweden, Thailand, Tunisia, Turkey, Ukraine, United Arab Emirates, Venezuela and Vietnam.

These highly specialized ratchet straps sewing machines have been developed taking into consideration the requirements of manufacturers of heavy duty ratchet straps & tie downs, that could reduce dependence on skilled workers.

In addition, the quality of the seams will be controlled by computer or special device, so you can reduce the cost of the final product, improve the quality and increase the production speed. These measures will allow us to successfully compete with other manufacturers - both European and Eastern (China), offering our customers high quality products at low prices.

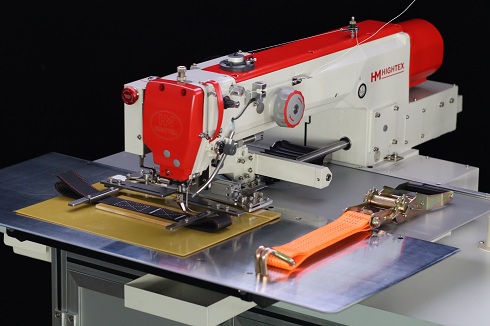

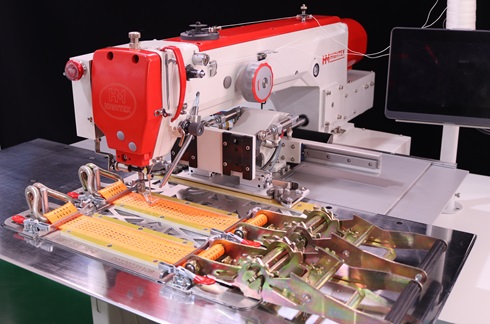

ASM911 Most affordable automatic programmable sewing machine for cargo lashing belts

This heavy duty automatic webbing sewing machine is one of the cheapest programmable electronic pattern sewing machines on the market. It must be said that its price is not synonymous with poor quality. Although inexpensive, this CNC programmable sewing machine is made of high quality materials and includes the most innovative clamping system. The 3-fold capacity large hook reduces the frequency of bobbin changes. Easily sew 10mm heavy duty webbing with thick thread up to metric size #10 (=T-270, V277, 840dx3).

Click here for video on YouTube

ASM911 can be with specialized clamp (custom made fixturing jig) for the manufacturer of cargo lashing belts & ratchet tie down strap. The advantage is zero-downtime, the machine can continuous working without any stop (no need of waiting for loading webbing, Ratchet and hook), due to its quick-changable pre-install jig. And in many cases, TWO WORKERS CAN OPERATE 3 MACHINES AT SAME TIME, GREAT FOR SAVING LABOR COST.

Click here for video on YouTube

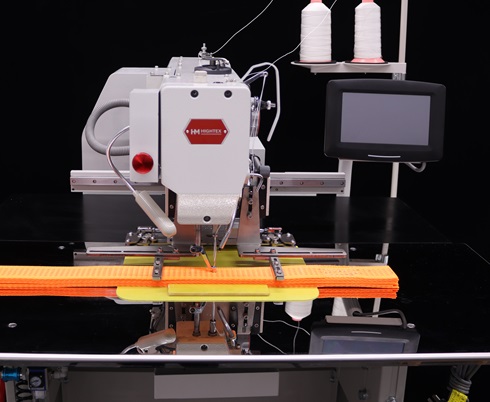

MLK700 Heavy Duty Automatic Lashing Strap Sewing Machine with Super Large Hook

A new generation of heavy duty programmable automatic sewing machine for cargo lashing belts is now launched! This heavy duty pattern sewing machine equipped with largest rotary hook in today market (6 times larger bobbin capacity), so the frequency of bobbin changes can be reduced greatly, leading to productivity enhancement. Easily stitch 14mm heavy duty synthetic webbing, with thick thread up to metric size #7 (= V415, T-400, 1300dx3). The bobbin thread detector will automatically stop machine when bobbin thread runs out, as a result, sewing operators can concentrate on their work without worrying about the bobbin thread, increasing the productivity, and it is possible to run 2 or 3 machines with only one person, great for saving labor cost.

Click here for video on YouTube

MLK500-3020N Automatic programmable pattern sewing machine with large clearance room behind needle and webbing positioning fixture for the manufacturer of heavy duty webbing cargo nets. The large space behind needle facilitates the easy and comfortable manipulation of work during sewing large size web cargo nets.

Click here for video

7273CNC/X Electronic controlled sewing machine for manufacturer of lifting slings and ratchet straps in United States

Automatic pattern stitcher with Barrel shuttle for heavy weight applications such as lifting slings, cargo lashing straps(reinforcement stitch or reinforced Eye), spanzet, military gear, backpack, fall protection equipment, parachutes rigging, hoisting belts, rescue belts and other critical area that needs extra reinforcement stitch.

Click here for video

828 Economical automatic hot knife webbing cutting machine for American manufacturer of ratchet straps

Best budget automatic hot knife webbing cutting machine for heavy duty webbing straps in the production of cargo lashing belts, lifting slings, seat belts and safety harness.

Length of cutting blade: 150mm

Cutting thickness: 7mm cintas de Poliester y cintas de Nylon

Max. temperature of blade: 600C.

Watch video on youtube

828AM Heavy duty webbing point-marking cutter (heat cutter with marking)

828AM Heavy duty webbing point-marking cutter is an extra strong heat cutter and point marker for webbing straps. This affordable hot knife cutting and marking machine can automatically cut, seal and mark the positoin for subsequent sewing of height safety harness, seat belts, Ratchet straps / tie down straps, webbing lifting slings and military straps.

Click here for video on YouTube

828B Automatic webbing slings cutting machine (hot cutter) with automatic feeding equipment, for manufacturer of lifting sling, ratchet lashings strap, height safety harness in USA

This heavy duty hot knife webbing cutting machine is designed for heat cutting 200mm wide webbing made of Nylon, Polyester, Polypropylene. he temperature of top and bottom heating blades is up to 600 C. It is almost necessary to have automatic feeding device if you put lifting and lashing straps in trolly, instead of rolls.

Click here for video

828S Automatic strapping machine allows you to apply plastic straps completely autonomously, and with minimal human interaction. The compact automatic strapping machine is mainly used for strapping and packing small-sized articles such as cargo lashing straps, webbing lifting slings, climbing ropes, dog collars, harnesses & leashes.

Click here for video

828-UV60-WPS Fully automated webbing cutting, measuring, winding and packing machine for the manufacturers of lashing straps

The full automatic webbing cutting, winding and strapping machines allow you to produce cargo lashing belts completely autonomously, and with minimal human interaction. HighTex has machines for various applications, which through the vast experience of the HighTex Technical Service can be incorporated into production lines of multiple webbing slings industries, in order to reduce the labor required for cutting and sewing processes.

Click here for video

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!

|