71008R Extra heavy duty automatic pattern tacking machine and bartack sewing machine for ropes, slings, belts and harnesses

The major advantages:

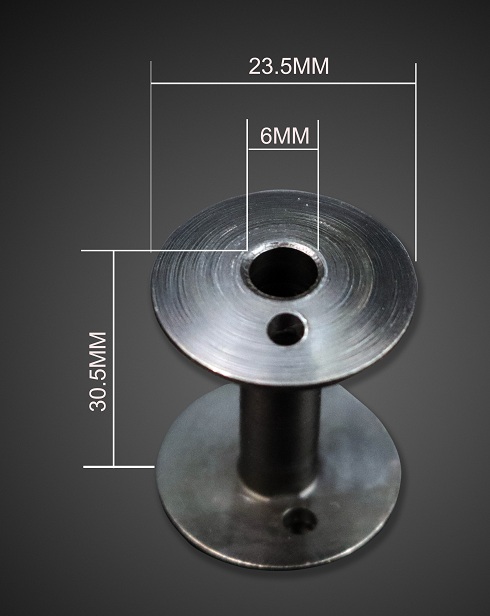

1. This heavy duty automatic pattern sewing machine / bar tacking sewing machine equipped with large Barrel shuttle hook that has been specially designed for sewing very heavy materials and thick thread;

2. The special large bobbin capacity reduces the number of bobbin changes and offer high efficiency in sewing products using extra thick thread up to metric size 7* (=V415, T-400, 1300dx3);

3. Wear resistance is improved, the shuttle hook lubricating system and filtering system extending the service life and enabling long-term use;

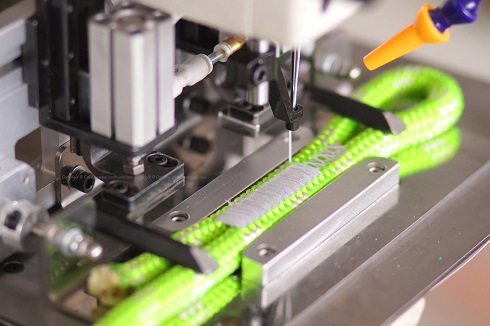

4. The sophisticated clamp tightly hold the rope in all direction that avoid jumping or moving during the sewing. HighTex is the only maker of machine that offers this type clamp;

5. The optional clamp is available for stitching up to 18mm thick synthetic harness webbing, for the production of height safety harness, fall protection equipment and lanyard products;

6. Built-in bobbin winder within operator's view. Automatic shut-off when the bobbin is full;

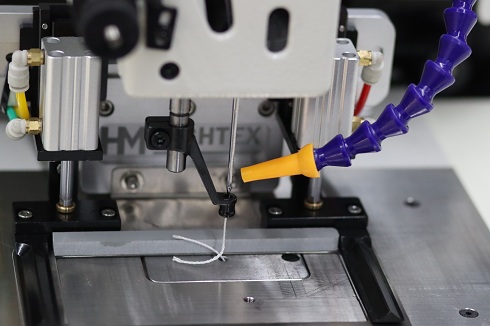

7. The needle cooler blows air to the needle, thereby preventing thread breakage caused by hot needle;

8. Free programmable (free software), updating and storage easier, it allows you to custom made safety harnesses, lanyards, climbing ropes and fall protection equipment;

9. Excellent stitch pattern and constantly tight stitch formation due to its advanced pneumatic system, strong needle penetration force and custom made fixture;

10. Newbie friendly pattern making system, it is always a challenge for beginner to create new sewing pattern (design, program), we've got the perfect line-up of easy and beginner-friendly sewing patterns to allow a stress-free, and fun introduction to sewing;

11. This heavy duty automatic programmable sewing machine comes with affordable price and extremely low maintenance costs;

12. Each machine supplies with comprehensive spare parts package that allow you to service, maintain and repair the machine for long time without the need to buy spare parts;

13. We have in-house technicians who have over 20 years of combined experience in servicing and repairing these special sewing equipment, there is no problem that we cannot solve by email or video conference, that will insure your machine can be serviced with minimal downtime.

Applications:

For Bar-tacking (zigzag) ropes and cordage for Arborist climbing ropes, Climbing & Caving Ropes, Marine Ropes and Safety Rope.

For pattern tacking height safety harness, fall protection equipment, lifting slings, seat belts, military equipment, backpacks, full body safety harness with shock absorber, safety lanyards, safety belts, life vest, rigging products, saddles and parachute harness.

Rope netting industry include safety netting, sports netting, industrial netting, agriculture netting, boat safety lifeline netting, rigging floats...