Which automatic sewing machine is best for climbing ropes and safety ropes

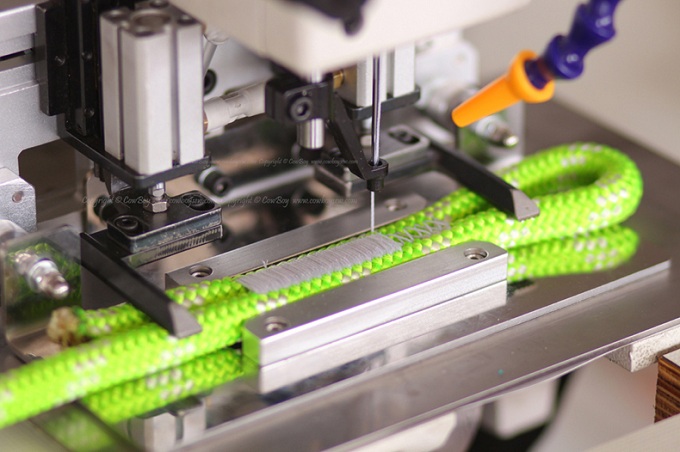

Heavy duty Bar-tacking can be widely seen reinforcing climbing popes,rescue ropes and other safey ropes, with strong and uniform stitch. Because most of the rope end bar tacking is used on is critical to survival, it is important to find the right heavy duty bar tacking sewing machine that can create extra safety and durability on the seam.

Today extremely heavy weight materials and thick sewing threads are used in the production of braided and twisted synthetic ropes made by Nylon, Polypropylene, Polyethylene and Polyester, for arborist rope, climbing/caving ropes, boat rope & marine rope, rescue ropes, rigging ropes, custom cordage and braided rope.

Over the years Hightex developed full range of computerized ropes sewing machines that optimize bar tacking to be consistent and of high strength and quality. Sewn eye terminations on ropes and cords are stronger than knots because rope-on-rope friction is eliminated along with the bending of the fibers.

All HIGHTEX heavy duty automatic pattern sewing machines and bar tacking machines will be thoroughly tested and gone over by Mingyuan Industrial Sewing Application Center.

Our field engineers configure these sewing automation equipment properly for customer sewing requirements. This includes building all the necessary clamping, jigging and fixturing to accomplish the sewing task, testing and checking all pneumatic, electrical, and computer systems for proper operation, programming the machine with all patterns supplied by the customers, and then testing the machine on samples that match exact customer specifications.

These operations save the end user many thousands of dollars in extra expense, eliminating the need for outsourcing the work required to get the machine in operating condition.

Now let us guide you to select a proper heavy duty automatic bar tacking sewing machine for your rope production.

1, DIAMETER OF ROPES

The diameter of your ropes will affect not only the minimum breaking strength, but also abrasion resistance, handling characteristics, weight. In production of normal climbing ropes and other safety ropes, we recommend below sewing capacity:

71008R: 8 to 16mm

7273PLK/R: 8 to 22mm

733PLC/R: 10 to 28mm

Usually climbing rope manufacturers need to join two ropes of different thickness, so you need to be clear the minimum and maximum diameters of your ropes.

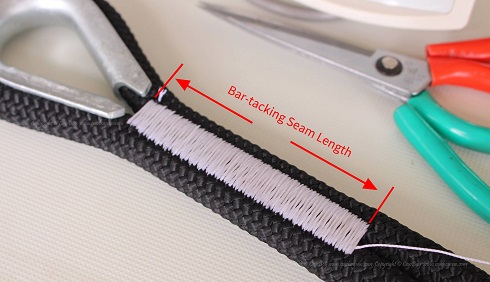

2, BAR TACKING SEAM LENTGH

The seam length will definitely effect on the breaking strength of safety ropes. In most manufacturing of climbing ropes, the bar tacking seam length is no more than 100mm (for saving sewing time). It can meet 22kN rope breaking strength test according to EN 1891:1998 specifications. If you need longer bar tacking seams on your climbing rope, for extra breaking strength or special purpose, a custom made clamp may be required.

71008R max seam length: 130mm

7273PLK/R max seam length:150mm (200mm length is possible by custom made clamp)

733PLC/R max seam length: 250mm

3, SPEED OF SEWING MACHINE

Sewing speed biggest concern for customers buying their sewing equipment, so it is better to choose a highest speed bar-tacking sewing machine that can sew the thickness of ropes.

71008R sewing speed:200-350RPM (depends on rope density and thickness)

7273PLK/R sewing speed: 200-800RPM (depends on rope density and thickness)

733PLC/R sewing speed: 150-250RPM (depends on rope density and thickness)

4, ROPE LINEAR DENSITY

In view of same rope thickness, the linear density has great effect on stiffness of the climbing ropes. The three most common safety rope materials are nylon, polyester and polypropylene. For some extra rigidity & cut resistance synthetic fiber ropes (tenacity is over 1000 (g/denier), you need much heavier bar tacking machine or stronger needle penetration force.

So if you are to stitch extra stiff ropes for manufacturing military ropes, marine ropes, fire rescue ropes and other industrial ropes, it is better to send some rope material for testing, before order!

5, PRODUCT RNGE

If you are a small safety rope manufacturer and want to purchase only one automatic bar tacking sewing machine for stitch both climbing ropes and safety harness belts, 71008R is the best solution. You can sew both round ropes and flat harness webbing by changing the clamp/fixture, see below video links (Note: with 71008R the max. sewing pattern of climbing harness is 130x60mm)

Video for sewing climbing rope

Video for sewing safety harness

6, PARTS AND WARRANTIES

Now review the parts availability and the warranties for the machines you’re considering. If your production line is running and something breaks within the warranty period, does the supplier have the part on hand? How long will it be under warranty? How long will it take to receive replacement parts when you order them?

When choosing a machine, spare parts availability is something that is often overlooked. If parts take weeks or months to get, your operation may be down during that period, so it is important to verify that parts are available and in a timely manner.

Below is the quality guarantee of HighTex automatic rope sewing machines (THE WARRANTY INCLUDED COMPUTERIZED SYSTEM, BOARDS, SERVO MOTORS, ELECTRONIC COMPONENTS AND ALL OTHER SPARE PARTS FOR MECHANICAL WEAR, BUT NOT INCLUDED SHUTTLE HOOK AND SEWING NEEDLE.)

71008R warranty starts from date of delivery: 36 months

7273PLK/R warranty starts from date of delivery: 24 months

733PLC/R warranty starts from date of delivery: 24 months

Note: above recommendation base on optimal stitch formation. A medium weight computerized sewing machine may be able to sew thick and dense harness webbing, but when running faster, it may see more wear and parts breakage. And you cannot obtain perfect sewing quality. See below photos of seam quality (bottom side of the rope), the right thread tensioning is perfect, but the left stitch balance is poor, you can see the knots, because the thread take up lever is not strong enough, cannot pull bobbin thread to the middle of rope. It not only influences the appearance of the finished product, also badly reduces the breaking strength of safety ropes.

Why does HighTex require samples from the customer when setting up an automatic rope sewing machine?

When writing climbing and security rope specifications, you should not neglect specifying the proper number of stitches per inch that should be used in your ropes and cordage. Why? Because the number of stitches per inch can have a direct influence on the seam strength and stitch appearance.

Obviously, the seam strength is dependent on a number of factors including: (1) rope materials; (2) rope density and thickness; (3) thread strength/thread type and size; (4)stitch count/number of stitches per inch; (5)weakening material from piercing with needle (type and weight of the Fabric); (6)pattern of sewing; (7) stitch balance (thread tensioning).

Generally, the more stitches per inch, the greater the seam strength, but it takes longer time in production. Furthermore, there are rare cases where adding stitches per inch can actually damage the rope fibers so that the seam is weakened, however, this only happens on specific rope fibers that can be damaged by excessive needle penetrations.

If you are not sure about the stitch count, thread size, needle size and sewing pattern, you can send us:

1) All types of ropes and cordage you are manufacturing;

2) With specific strength of each type rope and cordage;

3) Different size of threads you are using (testing with same quality of thread)

We will:

1) sew ropes with different thread size, and check the breaking strength

2) We will work out your "Prototypes" & make it to your specifications.

3) We will help you design best sewing solution for your rope sewing production (Avoid wasting time, material and capacity).

What is the difference between HighTex automatic climbing rope sewing machines and other Chinese heavy duty automatic sewing machines?

Enter Hightex --- a corporation founded on the principle of providing customized sewing automation for all phases of the heavy weight sewn products industry.

Other companies that manufacture sewing machines do exactly that -- they assemble components and test for correct operation, then ship the machine to the end user, unprogrammed, untested, without the proper jigging and fixturing necessary to complete the sewing projects of their customers.

So the customers must then hire an engineer to program their patterns into the machine, hire fabrication shops to build the required fixtures to hold the material, test the machine on a pre-production level, and then train employees and personnel to operate the machine. Such projects of a monumental undertaking require thousands of dollars, and in some cases tens of thousands of dollars to accomplish.

The first advantage of Hightex automatic industrial sewing machines is the customization.

We realize that customized sewing solution is the most suitable product for the highest possible productivity and quality. Our sale engineers will make clear your detailed sewing requirement, select the right machine for your application. Then our field engineers will build all the necessary clamping, jigging and fixturing to accomplish the sewing task, configuring these sewing equipment properly for customer sewing requirements.

The second advantage of Hightex sewing automation equipment is "Ready-to-Operate" (customers can use the machines immediately when they receive).

All HighTex heavy duty automatic pattern sewing machines and bar tacking machines will be thoroughly tested and gone over by Mingyuan Industrial Sewing Application Center.

This includes testing and checking all pneumatic, electrical, and computer systems for proper operation, programming the machine with all patterns supplied by the customers, and then testing the machine on samples that match exact customer specifications.

These operations save the end user many thousands of dollars in extra expense, eliminating the need for outsourcing the work required to get the machine in operating condition.

The third advantage of Hightex is the Spare Parts Package.

At Hightex, we realize how critical it is to keep your automation running. Let's face it, equipment breaks and machines malfunction. The key objective in a manufacturing environment is to minimize unplanned downtime. This package provides the necessary parts for the first 3-4 years of operation.

You can purchase the spare parts package together with machine, then no need to order any parts during this period.

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!

|