MLK700 Heavy Duty Programmable Automatic Pattern Sewing Machine with Super Large Hook ( 6 times larger bobbin capacity) for safety harness, webbing lifting slings,cargo lashing strap and other heavy-weight materials

The major advantages:

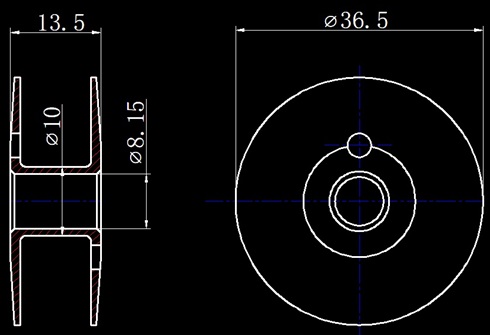

1. This heavy duty programmable electronic pattern sewing machine equipped with largest rotary hook in today market;

2. The 6 times larger bobbin capacity reduces the number of bobbin changes and offer high efficiency in sewing products using extra thick thread up to metric size 7* (=V415, T-400, 1300dx3);

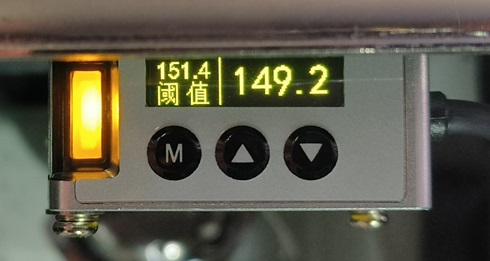

3. The bobbin thread detector will automatically stop machine when bobbin thread runs out, as a result, sewing operators can concentrate on their work without worrying about the bobbin thread, increasing the productivity, and it is possible to run 2 or 3 machines with only one person, great for saving labor cost;

4. The thread trimmer offers outstanding reliability and durability. The ideal application for the device is the sewing of height safety harness and cargo lashing belts with thick synthetic threads;

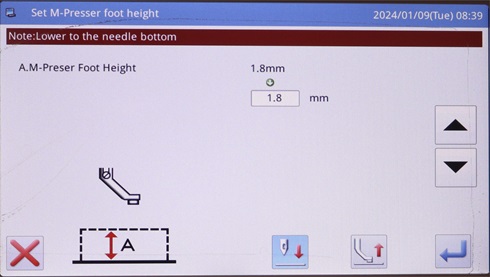

5. Presser foot control mechanism always provides uniform thread tightness (when thickness of material has been changed, the height of stepping presser foot is changed accordingly without tools required);

6. The high-rigid feeding system (double shafts) provides pinpoint accuracy and beautiful stitches;

7. The needle cooler blows air to the needle, thereby preventing thread breakage caused by hot needle;

8. Additionally, we have 20 years of experience providing turn-key programmable sewing machine systems to a global market. Vast experience in serving customers from the productions of cargo lashing straps, safety harnesses and lifting slings. HighTex has machines for various applications, which through the vast experience of the HighTex Technical Service can be incorporated into production lines of multiple textile slings industries, in order to reduce the labor required for sewing processes.

Applications:

Cargo webbing/tie-down webbing: heavy duty ratchet straps, lashing straps and tie down straps, load restraint equipment, cargo restraint ratchet strap; Safety harness webbing: safety harnesses, full body harness, fall protection harnesses, seat belts, screamers (shock absorbing sling), backpack straps, rescue belts, safety lanyard, slackline webbing; Webbing for lifting and hoisting (nylon or polyester): lifting slings, crane slings, rigging slings, tow strap, recovery strap; Military webbing: parachute harness, military straps, army vest, military equipment & tactical gear