FIBC911-400H Large area high speed automatic pattern sewing machine perfect for stitching lifting loops (belts) of cross corner Big Bags/FIBC Jumbo Bags/Bulk bags

The major advantages:

1. From now on sewing of Bulk Bag lift loops will be quicker and easier, – don’t waste your time, program your sewing on one lifting loops and you will see savings in no time.

2. Computerized sewing machine FIBC911-400H has achieved increased productivity with its maximum sewing speed of 1800 sti/min and beautifully finished seams with its new feed control system.

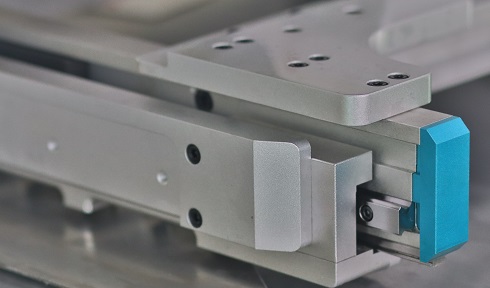

3. This new design and robust rail system create more stability of arm/rail movement on this machine. The machine provide the highest quality sewing exactly the way it is programmed even at high speed sewing with maximum performance according to each sewing area.

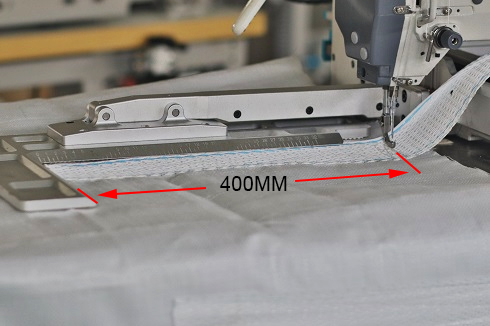

4. The max. sewing length (Y- axis) is up to 500mm that allow you insert machine arm into tubular body of Big bags, bulk bags & jumbo bags. The most common cross corner lift loop or corner seam lift loops size is 10 inches in free height, this sewing length cover all demands of modern FIBC industry.

5. The scale on pressing frame is very helpful to position the lift loops. It provides good reference, when you attach the lifting loops onto body of the FIBC, and control the size of “arch” over each corner.

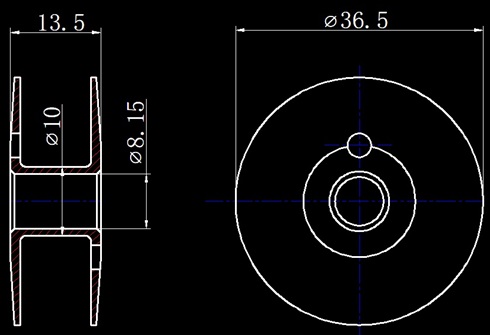

6.This heavy duty programmable electronic pattern sewing machine equipped with largest rotary hook in today market;

7.The 6 times larger bobbin capacity reduces the number of bobbin changes and offer high efficiency in sewing products using extra thick thread up to metric size 7* (=V415, T-400, 1300dx3);

8. This Bulk Bag lift loops sewing machine is free programmable, so you can create any sewing pattern (for example X-Box, double W etc.) when tailor-made Big Bags for any industry.

9. One-person operation, great for laboring saving! This machine standard euipped with FIBC fabric pulling system that can automatically unroll Big Bag body, it allow you to easily position the lifting loops and complete sewing tasks more precisely and in less time, by single person.

10. The new technologies of this machine provide optimal conditions for sewing lifting loops on FIBC Bulk Bags. For example FIBC fabric unrolling system, automatic thread trimmer, frame's scale. And the belt guard provides full and complete protection of the motor pulley and belt. This will greatly reduce any chance of operator injury.

10. These automatic FIBC lifting rope sewing machines will be completely assembled, thoroughly tested and serviced, ready to operation out of box. With no need for a technician and skilled workers!