Which automatic sewing machine is best for ratchet straps?

In today's ever widening world of heavy duty automatic sewing machines, how can a potential customer protect their interests and make a wise investment in a computerized sewing solution? How can any potential customer of automatic sewing machines know that they will be getting a machine suited for the job task they are trying to accomplish?

Now let us help you select a right "Ready-to-Operate" Sewing Automation Equipment for your manufacturing of Ratchet Lashing Straps / Tie-Down Straps:

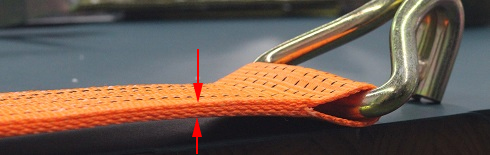

1, TOTAL THICKNESS OF CARGO WEBBING

Sewing thickness is the first point you need to consider when select an industrial sewing machine. It determined by height of presser foot lift, hook type, needle bar stroke, needle penetration force and thread tension, etc.

Most cargo lashing straps made of cargo webbing about 2mm thick, consider the overlap seam (composed by 3 ply webbing), the total thickness of lashing belts is no more than 7mm. So the ASM911 serial high speed automatic pattern sewing machine is the best selling machine in ratchet strap manufacturing industry.

If you are to make extra heavy duty ratchet straps (for example SpanSet), a stronger programmable sewing machine is necessary. This type ratchet straps and tie-down straps made of heavier cargo webbing (about 3mm thick), consider the overlap seam (composed by 3 ply webbing), the total thickness of lashing belts is upto 9mm. HighTex 7273CNC/X extra heavy duty programmable pattern sewing machine or MLK700/MLK900 heavy duty automatic sewing machine is specialist.

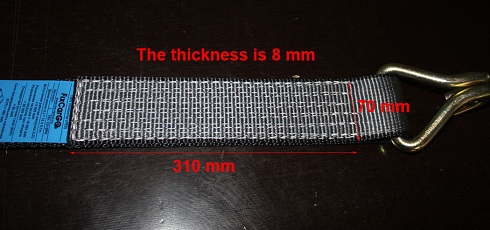

2, MAX. SEWING LENGTH

The maximum working area of programmable pattern sewing machine determines the maximum sewing area you can obtain. You should double check the maximum reinforced stitching area you need, both length (X) and width (Y) must be within range of machine's working area.

In today market, the width of cargo lashing strap is no more than 100mm, it is no challage for all automatic pattern sewing machines. So you just need to consider the max. sewing length as below picture (Note: just the length of the sewing seam, not theentire webbing).

3, SEWING THREAD SIZE

Thread size is the primary consideration for meeting the requirements of safety and durability seams for ratchet straps and tie-down straps. And sewing thread is very very important factor of the sewing quality. Some machines cannot handle large thread and some are better suited to small thread. Most cargo lashing manufacturers use sewing thread no more than 840Dx3 (=Metric#10,T-270, V277), but in United States, UK, Europe and Russia, more and more ratchet belts manufacturers use heavier sewing thead up to840Dx4 even

1260dX3.

4, SPEED OF SEWING MACHINE

Sewing speed biggest concern for customers buying their sewing equipment. Basically heavier industrial sewing machines run at slower speed (such as 7273CNC/X), ligher weigth sewing machine can run at higher speed (such as ASM911). So it is better to choose a highest speed automatic sewing machine that can sew the thickness of your ratchet lashing straps.

5, PRODUCT RNGE

If you are a small factory and want to purchase only one automatic sewing machine for sewing both cargo lashing straps and heavy duty webbing lifting slings, 7273CNC/X is the only solution, because ASM911 cannot sew heavy duty lifting slings.

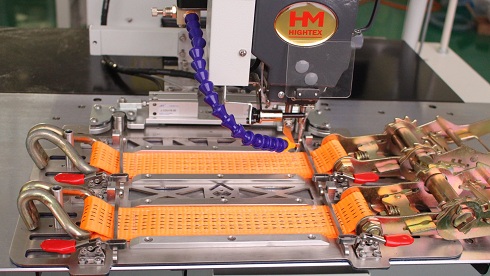

6, PRODUCTION VOLUME

If you are a small cargo lashing belts factory, just need one or two automatic sewing machines for sewing all sizes of ratchet strap, ASM911 is the economical sewing solution. These machines come with universal clamping fixture that is adjust able for all sizes of lashing straps. The problem is lower efficiency. Becase it take some time to prepare the ratchet straps before sewing, the machine must stop (waiting for operator to load webbing and ratchet), please check below video for better understanding.

Click here for video

If you are large manufacturer of ratchet lashing strap, ASM911 with specizlied sewing clamps (fixturing jig) is professsional solution. These machines come with custom clamping fixture that can continuous working without stop (zero-downtime), because each size ratchet strap with 2 clamps: one on table for pre-loading ratchets and webbing, another on machine for sewing. please check below video for better understanding.

Click here for video

Another advantage of ASM911 is 2 workers can operate 3 machines at same time (can save 30% labor cost): one worker for pre-installation material, another worker for operating the machines.

7, PARTS AND WARRANTIES

Now review the parts availability and the warranties for the machines you’re considering. If your production line is running and something breaks within the warranty period, does the supplier have the part on hand? How long will it be under warranty? How long will it take to receive replacement parts when you order them?

When choosing a machine, spare parts availability is something that is often overlooked. If parts take weeks or months to get, your operation may be down during that period, so it is important to verify that parts are available and in a timely manner.

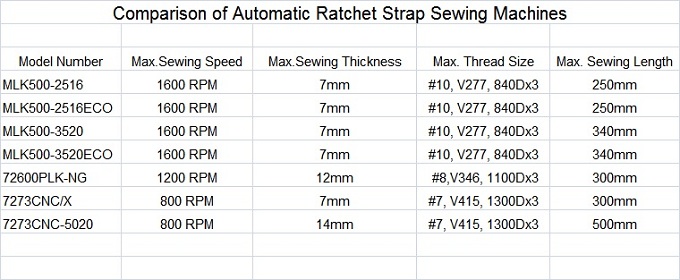

Specification Comparison Sheet Of Automatic Ratchet Straps Sewing Machine

In the past years, we have developed full range of specialized and high efficiency programmable electronic controlled pattern sewing machines (with small area, large area and extra-large sewing are) to meet security required in this field. These heavy duty CNC sewing machines are particularly capable of assembling extra heavy weight materials using very thick thread. Particular for the production of synthetic slings, straps, belts, ropes, harnesses and webbing for serving high-end industrial markets such as cargo lifting and lashing, safety & protection, fire and rescue, marine, automotive, aviation, military, custom-made lifting slings for offshore, marine and industrial applications.

Why does HighTex require samples from the customer when setting up a computerized automatic sewing machine?

We normally ask our customers to send sewn samples of the material that they want to use in the machine, as well as plenty of raw unsewn materials for testing, and also the thread that they would like to use for the sewn samples we run in the machine for the following reasons:

1. Certain factors will effect the sewing quality, for example stiffness materials, thickness webbing, nylon webbing woven density, thread size, thread type, sewing patterns, harness hardware / hooks and construction of rope lanyards. With sample material from the customer, we can custom make a sewing frame / clamp which will aggressively hold down the sample, and set the right thread tensions and sewing speed, as well as other calibration adjustments which will enable the machine to perform well in a production level environment.

2. We then test sew the machine over and over again to insure the machine will work flawlessly in production situations. This insures that you get a properly tested, adjusted, and ready to run solution out of the crate.

3. We will pre-program the machines according to the customers sewn sample and make a prototype of the customers production sample, so the customer can start production immediately when the machine is received.

What is the difference between HighTex automatic ratchet strap sewing machines and other Chinese heavy duty automatic sewing machines?

Enter Hightex --- a corporation founded on the principle of providing customized sewing automation for all phases of the heavy weight sewn products industry.

Other companies that manufacture sewing machines do exactly that -- they assemble components and test for correct operation, then ship the machine to the end user, unprogrammed, untested, without the proper jigging and fixturing necessary to complete the sewing projects of their customers.

So the customers must then hire an engineer to program their patterns into the machine, hire fabrication shops to build the required fixtures to hold the material, test the machine on a pre-production level, and then train employees and personnel to operate the machine. Such projects of a monumental undertaking require thousands of dollars, and in some cases tens of thousands of dollars to accomplish.

The first advantage of Hightex automatic industrial sewing machines is the customization.

We realize that customized sewing solution is the most suitable product for the highest possible productivity and quality. Our sale engineers will make clear your detailed sewing requirement, select the right machine for your application. Then our field engineers will build all the necessary clamping, jigging and fixturing to accomplish the sewing task, configuring these sewing equipment properly for customer sewing requirements.

The second advantage of Hightex sewing automation equipment is "Ready-to-Operate" (customers can use the machines immediately when they receive).

All HighTex heavy duty automatic pattern sewing machines and bar tacking machines will be thoroughly tested and gone over by Mingyuan Industrial Sewing Application Center.

This includes testing and checking all pneumatic, electrical, and computer systems for proper operation, programming the machine with all patterns supplied by the customers, and then testing the machine on samples that match exact customer specifications.

These operations save the end user many thousands of dollars in extra expense, eliminating the need for outsourcing the work required to get the machine in operating condition.

The third advantage of Hightex is the Spare Parts Package.

At Hightex, we realize how critical it is to keep your automation running. Let's face it, equipment breaks and machines malfunction. The key objective in a manufacturing environment is to minimize unplanned downtime. This package provides the necessary parts for the first 3-4 years of operation.

You can purchase the spare parts package together with machine, then no need to order any parts during this period.

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!

|