Your advantages:

1. Premium components help increase the laser cutting machine lifespan (Leadshine stepper motor and drive made in United States, CSK Linear Guide made in South Korea, Sintec laser lenses made in Singapore and UNIENTI timing belt made in Japan);

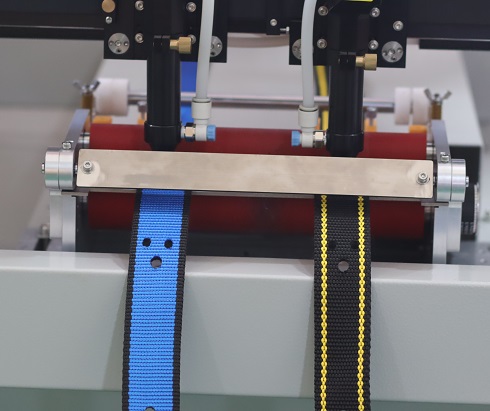

2. The CO2 Laser Cutter is capable of handling the toughest strip cutting tasks, it is perfect for angle cutting, shape cutting and hole punching a variety of products including harness webbing, seat belts, military straps, cords, Kevlar and more with ease;

3. This HighTex CO2 laser cutting machine is supplied with industrial-grade recirculating water cooling units, which are electronically connected to the laser cutter and protected by a flow sensor so that in the event the machine is powered on without the cooling unit operating correctly no power is supplied to the laser.

4. This affordable automatic laser cutting machine and engraving machine is widely used for cutting heavy duty webbing, seat belts, military straps, Kevlar, cords and ropes, ribbons and labels, Coated fabrics (Rubbers, felts, tapes,tubing), plastic, leather, wool, Acrylic plate, plexiglass, paper products and other applications;

5.The built-in USB port allows for PC connection and the transfer of designs (Compatible with AI, DLT, DXF formats, can conversion and editing with CAD data directly);

6. All units are thoroughly tested before delivery, ready to operate, very easy to use and maintain.

Applications:

safety harness & fall protection equipment, personal protective equipment, military & tactical gear, aerospace, marine engineering, automotive manufacturing, dog collars, harnesses & leashes and bespoke product manufacture