The 7360 machine is of an excellent design and the engineering behind this machine has been well regarded as the one of the best designs in the industry at present. This machine is a great improvement over older shoe patcher designs in that this new design is much more reliable, offers superior performance, larger bobbin capacity, and more precise stitches. The quality and fit and finish of this machine is very well regarded, and it rivals that of its European counterparts. The pricing of this machine is also much more affordable than other European machines being sold in the same class. The 7360 is also a huge step above other China made patcher machines, and it performs far better than these machines in every aspect.

The CowBoy 7360 is a heavy duty shoe patcher and leather sewing machine that truly stands out from the rest. With its advanced features, exceptional build quality, and superior performance, it's a machine that's perfect for serious buyers who demand the very best. With far better performance than its modest price, the 7360 is one that's sure to pay off in the long run, providing you with years of reliable, high-quality sewing performance.

Your advantages:

1. The extremely slender arm makes it possible to sew seams even in the most narrow parts and hard-to-reach areas of shoes,boots and small-sized tubular goods—making it an essential tool for cobblers, leather artisans, and upholstery professionals;

2. The top feeding foot can be turned in all directions, enables an individual change of the feeding direction without turning work, even during sewing;

3. The shoe patch sewing machine has a longer needle bar stroke than Adler 30-70 or Singer 29K allowing the operator to sew heavier leather. Easily sews a 10mm thickness with a 120 needle;

4. The large bobbin decreases the replacement frequency of bobbin thread, thereby reducing down-time, and allow you to sew with thick thread size up to V207 (Metric size #15 or 630Dx3 or T-210);

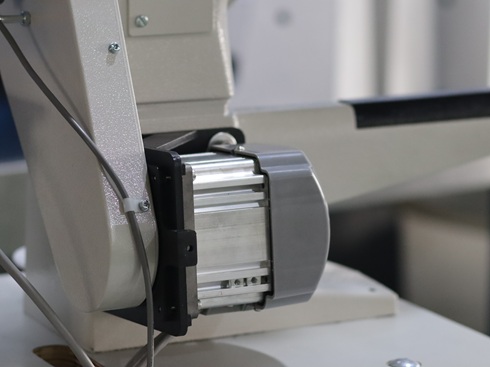

5. This heavy duty leather patcher | shoe repair machine is particularly user-friendly due to the Kinedyne HM-750SH low speed servo motor (Click here for detail) that allows slow, controlled stitching. It makes sewing detailed work much easier;

6. Its long arm (19 inches) is especially good for boots,shoes and cylindrical objects, and it easily handles both heavy and delicate work;

7. The automatic needle UP and DOWN needle positioning synchronizer makes it easy to control the machine, even when sewing complicated seams;

8. The built-in precision servo motor enables machine operation on any stand and table, also you can use it as hand-crank shoe repairing machine;

9. Double-ended needle plate with different size holes at the back end to accommodate various size needles;

10. This shoe repair (patching) machine is perfect closing seams (good stitch formation) both on delicate leather articles, sturdy shoes and orthopaedic applications;

11. The infinitely variable stitch length adjustment is useful for refinishing work;

12. Shuttle hook (Elastic Shuttle), bobbin and all other parts are interchangeable with PFAFF 8346 and CLAES 8346-30 large bobbin cobblers machines;

13. Most importantly, critical areas have been given a alloy coatings, the super hard alloy finish. High entropy alloy coating allow the parts to last up to 3 times longer than normal;

14.Besides the alloy coatings can prevent from rust, so provide an outdoor sewing solution, for example military tents repair, sewing patches on navy equipment covers, canvas gun covers in warships, and outdoor gear patches;

15. Machine noise is a critical indicator of quality and precision. A quiet machine generally indicates efficient operation, minimal friction, and often, higher build quality and precision engineering (Click here for video).

In well-maintained or high-precision shoe repair machines, low noise means:

1). Low Friction: The internal components are moving smoothly against each other with proper lubrication, minimizing wasted energy and wear;

2). Optimal Alignment: Parts are correctly aligned and balanced, preventing vibrations and knocking sounds that occur when components clash;

3). Precision Manufacturing: Tight tolerance parts fit together perfectly, which reduces the gaps that cause rattling or humming noises.

16. Sewing stand for work in seated position and sewing stand for work in standing position are available as option.

Applications:

Shoe repair, custom boots making, hockey equipment repair, dolls ,toys, leather handbags & wallets, leathercrafting & leatherworking, upholstery & curved stitching, round cases, tubular leather goods, baseball gloves, golf bags, team patches (put leather patches on hats,motorcycle jackets), leather vests, luggage, orthopaedicians, bandagists, sewing patches on navy equipment covers, canvas gun covers on warships, military tents & outdoor gear repair, as well as variety of small cylindrical items